How to improve LED highbay light heat dissipation

Time:2015-09-30 Views:2835 Compile:SUNPER

The reliability of the LED highbay light always depend on the amount of heat dissipated and thus improving heart dissipation is among the key technologies to be considered. In order to solve the excess heat generated by the chip through the heat sink, the most commonly used way is by cooling the body spread out. However, this method is a complex technical issue and thus use of the dimming technology is highly recommended.

LED highbay light heat dissipation problem

There are two new technologies that emerged after the development of the LED lighting products.

The first was due to the need to increase the single flux tube as well as inject a higher current density so that the chip will generate just the required heat.

The second one involves the structure of the package and due to the fact that the LED light source power increase, there is need to have more power of the LED chips like the COB LED highbay light. Since it generates a lot of heat, there is need to have a more effective heat dissipation structure as well as measures.

Currently, the overall efficiency of the LED highbay light heat dissipation is only 50 percent. Therefore, there is still a lot of power transforming to heat. The other issue is that the LED high current density plus modular lighting need a more concentrated heat and thus you must have good heat dissipation. To improve on the bulk LED highbay light, the heat level of SUNPER gives the following suggestions.

1. The LED chip should adopt a new structure, new technology and improve the LED chip junction temperature of the heat resistance. This will make cooling conditions needed to be achieved easily.

2. The reduction of the thermal resistance of the LED lights by comprising an adhesive material between the phosphor blend and the metal. This makes the resistance to be 10 per Watt or even less.

3. Reduction of the heat heating up by as much as possible. The design needs a better ventilation channel where it can spread it out immediately to always ensure that the temperature is less than 50.

4. The next suggestion is improving the heat dissipation level by one of the ways such as use of the heat pipes. However, remember to consider the cost factor when designing the cost of issues.

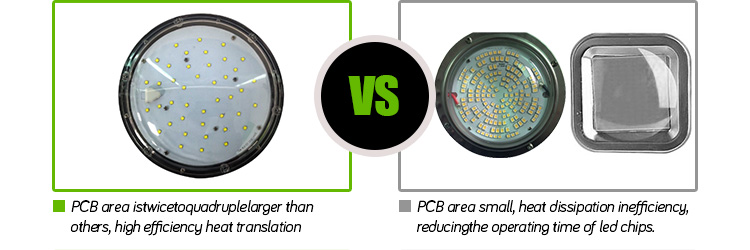

5. Adoption of the SMD chip LEDs which have less heat generated. Deign the PCB area to be more conducive to the total heat generated during the dispersion of the LEDs work. This will also help in extending the lifespan of the LED highbay light.

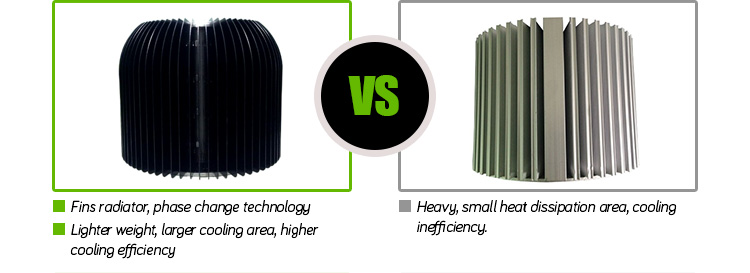

6. Increasing the LED highbay light radiator area. Cooling of the high power LEDs is very useful under the usual circumstances. The size of the area cooling has a direct impact on the cooling effect. Thus, there is need to maximize the cooling area so that heat dissipated is just as required thereby making it possible to work for longer.

In addition to the above suggestions, there is still need to improve the heat level by using good thermal conductivity materials. Right mechanical properties must also be met to ensure that you effectively achieve what you desire. It is worth noting that the temperature of the dust radiator needed should be small LED lamps.

Tags:LED highbay light; heat dissipation; SUNPER

More Posts

■ The LED chip dissipation of high bay lamps

■ LED Floodlights Heat Sink Selection

■ The current status of LED lighting Heat Dissipation Technology

The importance of the power factor to LED high bay luminaire

Next:Benefits of Using LED High Bay Lamp

User comments

Your current input 0 characters(Reply for at least 6 characters)。

Online Services

Mobile: +86 18938902515 (Mr.Allen)

Tel:+86 755 23159099

Fax:+86 755 61673151

E-mail: sales@sunper.net

zip code: 518108