Why heat sink is important in high bay LED fixture

Time:2015-11-11 Views:2707 Compile:SUNPER

Heat sink is among the most important features of the high bay LED fixture. There are many reasons contributing to this and here are just some of them. In the high power LED lights such as high bay LED fixture, the most challenging thing is the issue of heat problem which has been the focus of attention for a long time now. A lot of heat is usually generated when the high power of the LED lights work more and hence the need to cool the LED lamp for the lifespan of the device not to be affected a lot.

Since the birth of the LED heat dissipation by engineers who strived so much and finally found a project to counter the problem, there has been so many other new technologies as well as methods in quest to enhance the cooling efficiency. Currently, most of the engineers are focused on the study of the heat sink such as improving the heat sink material as well as increasing the heat sink area.

Two points generate a lot of heat

There are two major pints in which the high bay LED fixture generates a lot of heat when it is working. The two points include the power supply as well as the LED chips. These two points can be managed if the temperature is too high especially the high power LED lights like the LED high bay. Other parts likely to be affected include the LED flood lights. They usually produce a lot of heat and therefore if the high powered lamps get damaged, the replacement as well as maintenance cost is very high and thus the heat sink cooling effect is very important.

Solutions of heat dissipation

SUNPER has also come up with a solution too. On issues regarding the LED chips, the SUNPER uses the SMD LED. This does not mean that the SMD is better than the COB performance, both of them are good quality chips, it is only that the SUNPER uses it in order to solve the heat problem. SMD is simply a low-power chip and thus the heat generated is not significant. The design process of this company uses a large area of the PCB so that the heat generated can be decentralized to enhance the cooling effect. COB is also a good source since it has high power chips. The heat generated in the COB is usually concentrated in one place where it can be dispersed. The temperature of the COB chips is usually very high and this reduces the lifespan of the high bay LED fixture.

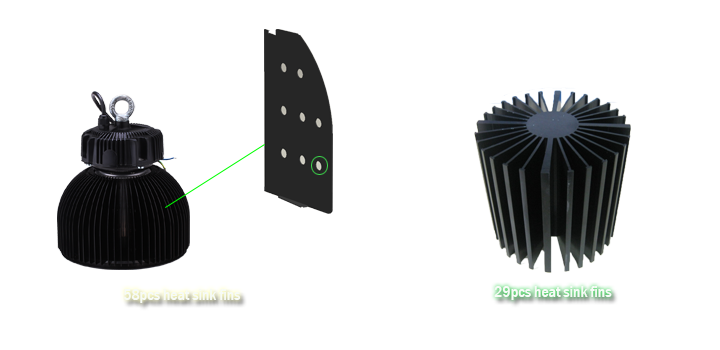

On the issue of the heat sink, the SUNPER uses phase change technology in order to increase the cooling area of the heat sink. SUNPER has also designed fins radiator such as 150 watts high bay LED fixture in which there are 58 pcs. This is far much better as compared to that of the manufacturer that contains 29 pcs only. The reason that 58 pcs is better is that for good heat dissipation, the area must be large.

To add on the above, the air flow is also very crucial factor for heat dissipation. Each fin contains 5 to 10 holes to help achieve the air flow inside the heat sink. If all the above is done, the LED products will always work longer as well as serve humanity better.

Sensors to use in high bay LED retrofit to save energy

Next:Knowing the best power supply to use for High Bay LED Lights

User comments

Your current input 0 characters(Reply for at least 6 characters)。

Online Services

Mobile: +86 18938902515 (Mr.Allen)

Tel:+86 755 23159099

Fax:+86 755 61673151

E-mail: sales@sunper.net

zip code: 518108