The LED chip dissipation of high bay lamps

Time:2015-09-09 Views:2690 Compile:SUNPER

The LED chip dissipation of the high bay lamps is the heat lost into the air during the lamp housing. If the heat is not very good due to the heat capacity of the LED chip being very small, there is a bit of heat accumulation that makes the chip junction temperature to increase rapidly. If it remains in the state of high junction temperature for long, the lifespan shortens. However, this may guide the chip to the external air to go through different ways especially the heat generated by the LRED chip. From this, it is correct to say that the high bay lamps actually include thermal conductivity as well as dissipation in 2 parts.

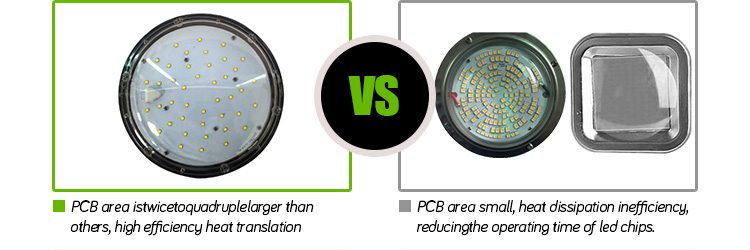

1. Thermal conductivity of the aluminum plate

Currently, most of the LED high bay lamps are using the aluminum plate. The aluminum foil circuit board electrically as well as thermally conductive so as to have adequate width and thickness. The thickness should be between 35m to 280m. The width is mostly covered using a substrate as a whole so as to heat generation. If the insulator layer is below the insulation performance, then it requires very good thermal conductivity. However, the two features which are used are somehow contradictory. They are usually the good conductors of thermal conductivity as well as poor insulator. It is also a bit difficult to do with good thermal insulation.

2. Plastic thermal

Even though the PCB has been resolved to the connection from the LED high bay lamps to the aluminum plate as the circuit board, it can transfer the heat into the aluminum plate. However, it is so unfortunate that this is not the final aluminum radiator. Basically, this aluminum plate is usually connected to the actual radiator up. The simplest way is to use the screws or rivets method of connecting to the radiator. Conversely, this method tends to form a gap of air. Thus, there is resistance generated by this small air gap and it may be larger than in the other thermal resistance by several times. You have to ensure that the plastic thermal is good fluidity or else the due smear will still lead to an air gap. It is also worth noting that thermal plastic adhesive is inadequate aluminum plate which is fixed to the aluminum radiator.

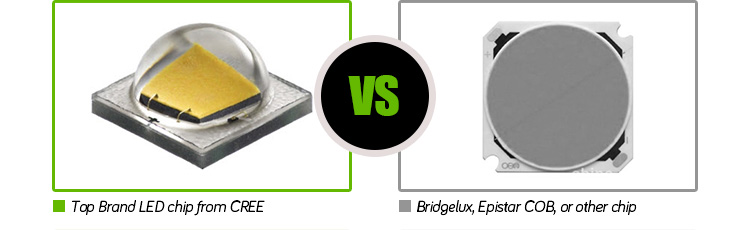

The heat pipe thermal

On most of the occasions, there is need to have heat generated by the LED high bay lamps to the fastest speed transfer to the heat sink. This is particularly important in the high power single chip having integrated LED. This is due to its great heat and power of about 50 watts to 100 watts. It is also very well focused and sometimes it is only 30mm. In such a case, it must use the heat pipe cooling. However, you need to know that it is only the heat pipe heat transfer to the distal end so as not to put heat into the air. Therefore, with even the heat pipe, you still require to have a regular aluminum radiator for dissipating heat.

The resistance of the system

The thermal conductivity of each of the portions of the system can be used to illustrate the thermal resistance. The LED high bay lamps chips have heat generated from the metal heat block out. It is first through the solder then to the aluminum substrate PCB via the thermal plastic and finally to the aluminum radiator. However, in order to fully understand the LED high bay lamps chip cooling process, it is preferably to use the concept of the thermal resistance. It is worth noting that heat is just like charge. This, the heat usually flow together just like the current does. The process flow is met with the resistance. The unit of the thermal resistance is the number of degrees in C per Watt. This is the flowing of every one watt of power that increases the number of degrees. If you are aware of the needed power dissipation as well as their resistance, you can effectively and easily determine how much it will rise. The greater the resistance, the more the heat will be flowing. If the temperature is a bit higher, then the thermal resistance will be smaller. If the heat flow is faster, then there will be small increase in the temperature.

More Posts

■ Main Factors That Determine the lifespan of LED Lightings

■ Choose A High Quality LED High Bay Fixture

■ The current status of LED lighting Heat Dissipation Technology

Production steps of the high power LED flood lamp

Next:100W LED High Bay replace 250W Metal Halide

User comments

Your current input 0 characters(Reply for at least 6 characters)。

Online Services

Mobile: +86 18938902515 (Mr.Allen)

Tel:+86 755 23159099

Fax:+86 755 61673151

E-mail: sales@sunper.net

zip code: 518108